RPET fabric or Recycled Polyethylene Terephthalate is a new reusable and sustainable material on the rise. Before recycling, PET (Polyethylene Terephthalate) is commonly known as Polyester. This can contain either pre or post-consumer waste.

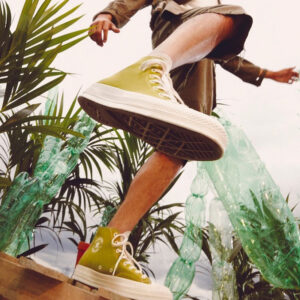

Considering rPET fabric is growing in popularity, companies are creating special edition products made from the material. Trendy retailers like Converse, GirlfriendCollective, and Rothys all have products made from the recycled material. First, to create products from rPET fabric, these companies must work with outside sources to obtain plastic bottles. Next, the bottles are mechanically broken down to melt into tiny flakes. The flakes are then to be spun into yarn. Finally, the yarn is woven into recycled polyester fabric. As a result, trendy sneakers by Converse, comfortable leggings by Girlfriend Collective, and sustainable shoes by Rothys are created. Customers of all ages can enjoy these polyester products.

Using a sustainable rPET fabric is a great idea when you manufacture it correctly. With a rising concern for the amount of plastics in our oceans and landfills, cleanup companies help reduce our carbon footprint. Cleanup organizations like Clean Ocean Action and 4Ocean are retrieving more plastic materials to be manufactured into materials like recycled polyester. The energy used to create rPET fabric is about 33-53% less than what it is to produce virgin polyester. Due to the demand of recycled polyester, we are saving our oceans and landfills from plastic materials; especially water bottles.

rPET Fabric: The Pros and Cons:

The Pros:

RPET is incredibly easy to recycle. PET bottles are easy to distinguish by their “#1” recycling label and is accepted by most recycling plans. Reusing plastic not only provides a better option than landfills, but it helps give it a second life. Recycling the plastic into these materials like polyester for example has the ability to decrease our need for using new resources. Over half of first time PET production is used to create recycled polyester fabrics. By using recycled PET, we are decreasing the need to create new textiles.

Consequently rPET provides a market for recycled plastics, recycling waste programs and recycled goods are seen as valuable pieces to consumers. According to EarthHero , “one year’s worth of recycling common plastics can create the equivalent energy savings of taking 360,000 cars off the road in the US.”

The Cons:

We know that rPET has the potential to be recycled. However, it is still plastic. Even though plastic can decompose or break down, microfibers or microplastics still remain. In its fabric form when washed, rPET can contain tiny plastic fibers that break off, making their way back to landfills or oceans harming its inhabitants. Needless to say, plastic waste is here to stay for quite some time. Although, renewing the life of already-made plastic products is a step in the right direction.

Unfortunately, even the recycling process may have negative environmental effects. It does take less energy to produce products from recycled plastics, but carbon emissions are still released in the process.

Why Recycling Still Matters:

Statistics by Greener Fabrics: a leading provider of rPET fabrics indicate (comparing to virgin polyester):

- Requires 85% less energy

- 65% fewer emissions: 50-65% less Carbon and Sulphur Dioxide

- Requires 90% less water

Plastic bottles take about 700 years to decompose, so getting them out of landfills and waterways is extremely important. In the decomposing process, the bottles are not completely broken down. Consequently, they become tiny microplastic pieces. Even if we can’t see them, they still harm the ecosystem.

Recycled PET is not yet a perfect solution, but it does still find new life for plastics. Creating a new life for plastic water bottles is a great start. On top of shoes and clothing made from rPET fabric, reusable shopping bags can also be created from this material; using shopping bags made from this material also cuts down on single-use plastic bags . Considering its pros and cons, rPET is the more sustainable option.